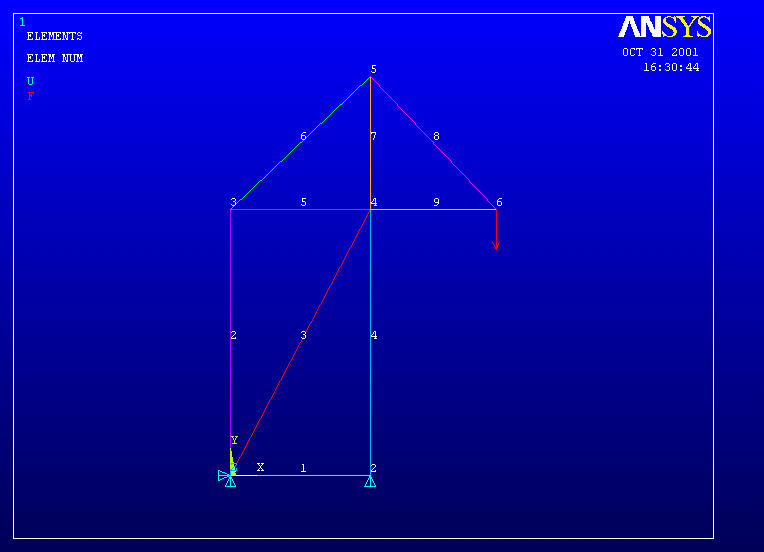

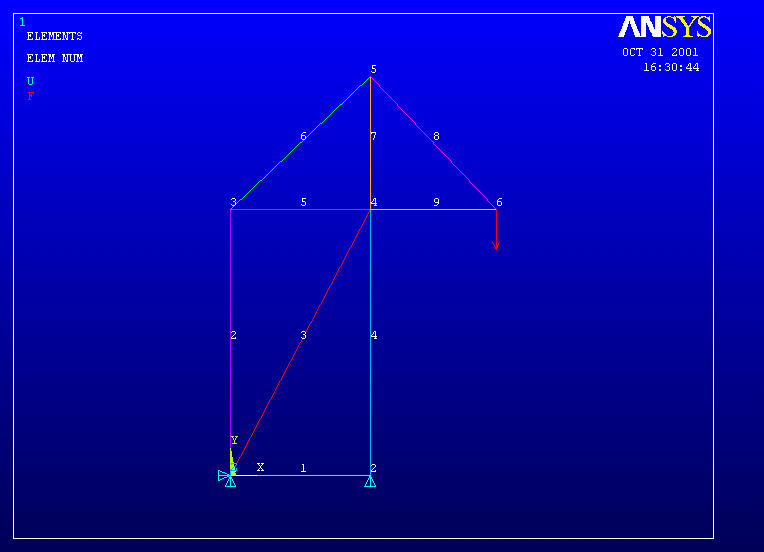

Truss2 – An example of the incorporation of multiple material and geometric properties in an ANSYS text file problem definition. Truss elements 1-5 are made of steel with 0.5 sq. inch cross section. Elements 6-9 are made of aluminum with 0.375 sq. inch cross section.

/FILNAM,truss2 /title Truss Sample Problem #2 /prep7 n, 1, 0.0, 0.0 ! Node 1 is located at (0.0, 0.0) n, 2, 10.5, 0.0 n, 3, 0.0, 20.0 n, 4, 10.5, 20.0 n, 5, 10.5, 30.0 n, 6, 20.0, 20.0 et, 1, link1 ! Element type; no.1 is link1 r, 1, 0.5 ! 'Real Constant' number 1 is 0.5 (the link Cross sectional area) r, 2, 0.375 ! Second cross sectional area ! with ANSYS Release 13 link1 has been replaced by link180 ! et, 1, link180 ! Element type; no.1 is link180 ! and 'real constant' replaced by 'sectype' and 'secdata' ! sectype, 1, link ! Type of cross section is link ! secdata, 0.5 ! Cross sectional area = 0.5 sq in !First Material mp, ex, 1, 3.e7 ! Material Property, Elastic modulus no. 1 mp, prxy, 1, 0.3 !Second Material mp, ex, 2, 1.e7 ! Second material mp, prxy, 2, 0.3 r, 1, 0.5 ! 'Real Constant' number 1 is 0.5 (Cross sectional area) r, 2, 0.375 ! Second cross sectional area !The following elements are element type 1, made of material #1, with area real constant #1. real, 1 ! Set real & material properties for elements defined next. mat, 1 en, 1, 1, 2 ! Element Number 1 connects nodes 1 & 2 en, 2, 1, 3 en, 3, 1, 4 en, 4, 2, 4 en, 5, 3, 4 real, 2 ! Switch to second set of real & material properties mat, 2 !The following elements take new properties. en, 6, 3, 5 en, 7, 4, 5 en, 8, 5, 6 en, 9, 4, 6 d, 1, ux, 0. ! Displacement at node 1 in x-dir is zero d, 1, uy, 0. ! Displacement at node 1 in x-dir is -0.125 d, 2, uy, 0. f, 6, fy, -1000. ! Force at node 6 in y-direction /pnum, elem, 1 ! Plot element numbers eplot ! Plot the elements /pbc, u, , 1 finish /solu ! Select static load solution antype, static solve save finish /post1 etable, stress, ls, 1 ! Create a table of element stress values